Smart Automation Turbine Flowmeter Volumetric Flow Measurement Instrument Supplier

| Accuracy class: | class 0.5, class 0.2 |

| Ambient temperature: | -20℃~60℃ |

| Medium temperature: | -20℃~+130℃ |

| Signal output: | Pulse signal, 4-20mA current signal, HART, RS485 communication, suitable for communication with PLC DCS.Waiting for the system to be used in conjunction. |

| Explosion proof sign: | ExdIICT6 |

| protection grade: | IP66 |

The LWGY series Liquid Turbine Flowmeter is mainly composed of a housing, a front guide frame, a shaft, an impeller, a rear guide frame, and amplifiers and converters with magneto electric converters.

When the fluid passes through the flowmeter, it impacts the impeller blades, causing the impeller to rotate. The periodic rotation of the impeller changes the magnetic flux of the magneto electric converter, which outputs a pulse signal through magneto electric conversion. The number and frequency of the pulse signal are proportional to the flow rate and magnitude passing through the flowmeter.

Basic parameters:

Measurement medium: clean liquid, viscosity ≤ 5mP · S

Accuracy levels: 0.2, 0.5, 1

Sensor materials: 304 stainless steel, 316 stainless steel, 304+20 # carbon steel, aluminum alloy; Impeller: 2Cr13, duplex steel;

Bearing: Made of wear-resistant materials, sturdy and wear-resistant, the unique design ensures that the bearing will not be crushed by sand and gravel.

Usage conditions: Medium temperature: -20 ℃~130 ℃; Environmental temperature: -20 ℃ to+70 ℃; Relative humidity: 5% to 90%

Signal output function: pulse signal, 4-20mA current signal, HART, RS485 communication, suitable for communication with PLC DCS

Waiting for the system to be used in conjunction.

The flow converter displays instantaneous flow and cumulative flow.

Working power supply: External power supply:+ 24VDC ± 15% (for pulse, 4-20mA output, RS485 communication)

Internal power supply: 3.0V10Ah lithium battery

Protection level: IP66

Explosion proof grade: ExdIICT6

Signal line interface: Basic type: Hausman connector; Explosion proof type: Internal thread M20 × 1.5

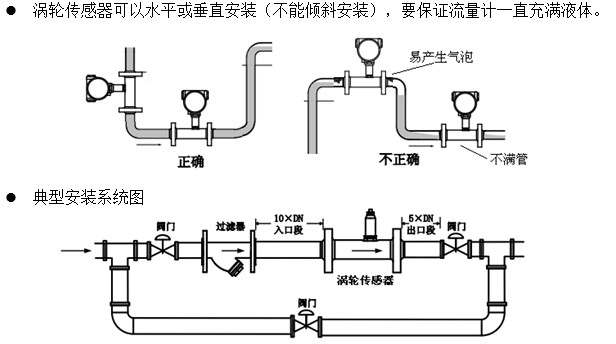

Installation of turbine flowmeter:

Signal Transmission for Liquid Flow Meters:

Reliable Remote Signal Output for Liquid Flow Measurement

Liquid flow meters are widely used in water treatment, chemical dosing, food processing, and industrial pipelines. To meet modern monitoring requirements, liquid flow meters are equipped with multiple signal transmission options for long-distance and real-time data collection.

- 4–20 mA Analog Output: Provides stable and interference-resistant transmission over long distances. Ideal for continuous liquid flow monitoring and integration with PLC and DCS systems.

- Pulse / Frequency Output: Suitable for total flow calculation, batching systems, and water consumption measurement in municipal and industrial applications.

- RS485 with Modbus RTU Protocol: Enables digital communication for accurate remote monitoring. Supports multi-point networking and centralized data acquisition.

- HART Communication (Optional): Allows remote configuration, diagnostics, and calibration without interrupting operation.

Application Value:

- Real-time liquid flow monitoring

- Reduced manual meter reading

- Improved data accuracy and traceability

Automation Capability of Liquid Flow Meters:

Seamless Integration into Automated Liquid Control Systems

Liquid flow meters play a key role in automated process control, especially where precise flow regulation is required.

Fully compatible with PLC systems (Siemens, Schneider, Mitsubishi, Allen-Bradley, etc.)

Supports SCADA and DCS platforms for centralized control and visualization

Enables automatic valve and pump regulation based on real-time flow feedback

Suitable for closed-loop control in dosing, mixing, and filling processes

Automation Benefits:

- Improved process stability

- Reduced operator intervention

- Enhanced production efficiency and repeatability

IoT & Smart Monitoring for Liquid Flow Meters:

Smart Liquid Flow Measurement with IoT Connectivity

IoT-enabled liquid flow meters allow users to monitor liquid flow data anytime and anywhere.

- Wireless Communication Options: NB-IoT, LoRaWAN, Wi-Fi, or Ethernet (depending on configuration)

- Cloud Platform Integration: Flow data is transmitted to cloud servers for real-time access, historical analysis, and reporting.

- Remote Monitoring Dashboard: Displays instant flow rate, cumulative volume, alarm status, and system diagnostics.

- Predictive Maintenance Support: Data analytics help detect abnormal flow patterns, leaks, or blockages early.

IoT Advantages:

- Centralized liquid flow management

- Lower maintenance costs

- Support for smart factories and digital water systems

Welcome to ask us for detailed product manuals.

- Digital Turbine Flowmeter For Sale

- Double Spiral Rotor Flow Meter

- intelligent liquid flow meters

- liquid flow meters manufacture

Tags: