Flowmeter Technology Manual for the Oil Storage and Transportation Industry

Release time: 2026-01-26

Table of Contents

In the oil storage and transportation industry, flowmeters act as “industrial data sentinels” that monitor fluid dynamics. They not only capture real-time instantaneous flow data but also accurately calculate cumulative flow over specific time periods. With their outstanding measurement accuracy, flowmeters serve as the authoritative basis for custody transfer while deeply empowering production automation control, pipeline operation monitoring, and early warning systems. They are a critical foundation for ensuring efficient and safe industry operations.

As a Tier-One supplier to China National Petroleum Corporation (CNPC) and a strategic partner of China Petrochemical Corporation (Sinopec), Hefei Jingda Instrument provides a range of core flowmeter products that serve as trusted “industrial data sentinels” in the oil storage and transportation sector. These products are deeply integrated across the entire domestic oil storage and transportation value chain, providing precise measurement support for extraction, pipeline transmission, and storage operations in major oilfields. At the same time, they are exported to more than 20 oil-producing countries across Asia, Africa, and Latin America, achieving extensive global application and coverage.

Flowmeters can be classified from multiple perspectives, mainly based on operating principle, application environment, and fluid characteristics. Below are the most commonly used flowmeter types in oil storage and transportation scenarios, along with their key technical characteristics.

I. Basic Concepts: What Is Flow?

Liquids and gases are collectively referred to as fluids. The quantity of fluid passing through a fixed cross-sectional area per unit time is defined as flow, which is one of the core process parameters in oil storage and transportation. Flow directly affects transport efficiency, measurement accuracy, and process control precision.

Key Flow Parameters and Formulas

Volumetric Flow

Based on fluid volume and is the most commonly used flow parameter in field applications.

Formula:

QV = V × F

Where:

QV = volumetric flow

V = fluid velocity

F = pipe cross-sectional area

Mass Flow

Based on fluid mass and suitable for high-accuracy measurement applications.

Formula:

Qₘ = ρ × v × F

Where:

Qₘ = mass flow

ρ = fluid density

v = fluid velocity

F = pipe cross-sectional area

Totalized Flow

The total amount of fluid passing through a system over a specific period. It is the core basis for custody transfer and material accounting and is calculated by continuous accumulation through the flowmeter.

II. Common Flowmeter Types and Characteristics

1. Positive Displacement Flowmeters (PD Flowmeters)

Positive displacement flowmeters are the mainstream devices used for crude oil custody transfer. Their operating principle involves mechanically dividing the fluid into fixed-volume units and calculating total flow by counting these units. They offer high measurement accuracy and excellent stability and are suitable for most petroleum media. Common types and features include:

Scraper Flowmeters

High accuracy and repeatability, wide turndown ratio, low noise, large flow capacity, sand-resistant, long service life, and strong adaptability to viscosity variations. They tolerate a certain amount of solid particles and are suitable for large-diameter pipeline applications. These flowmeters are core devices for crude oil, residual oil, and refined oil transfer and custody transfer.

Hefei Jingda Instrument’s LBJ series metal scraper flowmeters are widely used in crude oil extraction and pipeline transportation in oilfields such as Changqing, Daqing, Yumen, and Qinghai.

Oval Gear Flowmeters

Excellent viscosity adaptability—the higher the viscosity, the smaller the leakage error and the higher the measurement accuracy. Designed specifically for high-temperature, high-viscosity media such as crude oil and refined products. No viscosity compensation is required, and the structure is simple and reliable, with no special requirements for upstream or downstream flow conditions.

Hefei Jingda Instrument’s LC series oval gear flowmeters are widely applied in crude oil pipeline transmission and refined oil storage and transportation in oilfields such as Jianghan.

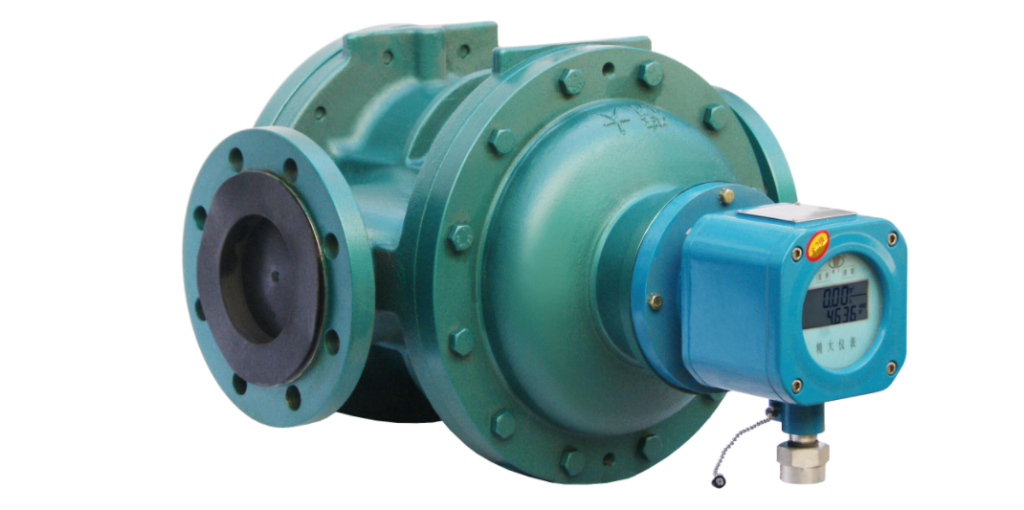

Roots Flowmeters (Lobe Flowmeters)

High accuracy that meets custody transfer standards, with outstanding operational stability, particularly suitable for diesel measurement.

Hefei Jingda Instrument’s LL series Roots flowmeters support efficient refined oil storage and transportation operations in oilfields such as Dagang.

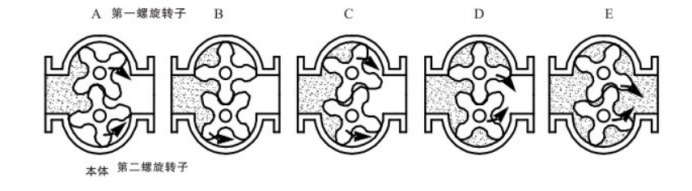

Dual-Rotor Flowmeters

High accuracy, strong anti-interference capability, wide turndown ratio, low operating noise, and superior stability compared to conventional PD flowmeters. Suitable for crude oil, refined oil, corrosive media, and certain high-viscosity fluids.

Hefei Jingda Instrument’s LLT series dual-rotor flowmeters play an important role in production and operation across oilfields including Tarim, Yumen, Daqing, and Qinghai.

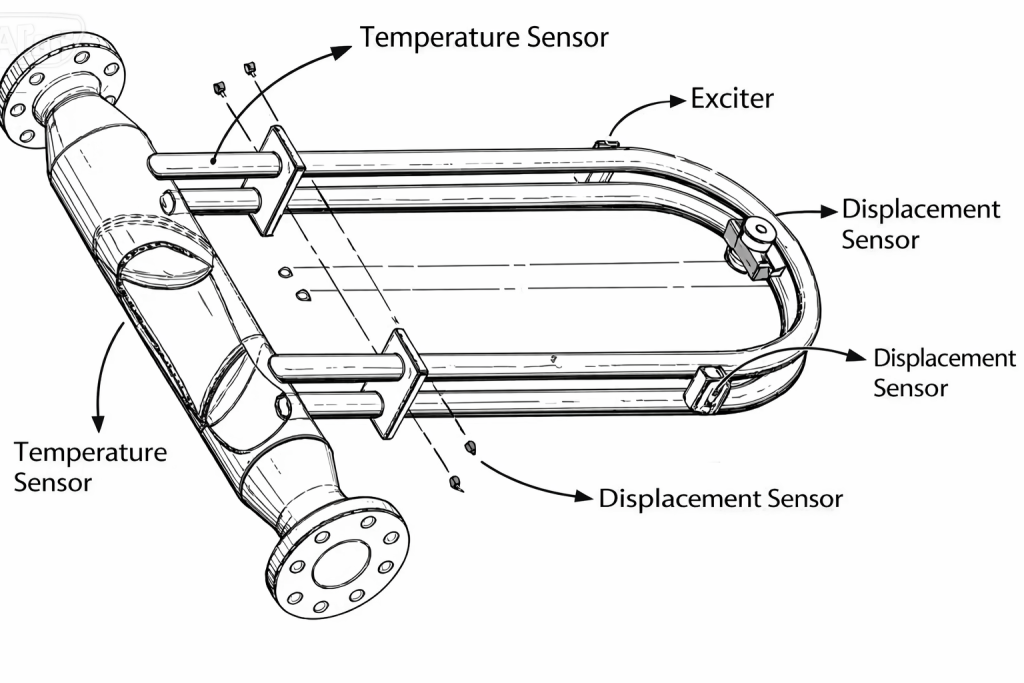

2. Mass Flowmeters (Coriolis Mass Flowmeters)

Coriolis mass flowmeters are direct mass measurement instruments that operate based on the Coriolis force generated when fluid flows through vibrating tubes. They do not require density conversion and are the preferred choice for high-precision, multi-parameter measurement applications.

These flowmeters can display instantaneous and cumulative mass flow, volumetric flow, temperature, and density on an LCD screen. They support pulse and current outputs and feature RS-485 communication capability.

Technical Features:

Direct mass flow measurement with simultaneous output of density, volume, and temperature; unaffected by changes in fluid temperature, pressure, or viscosity.

Applicable Media:

Oil products and chemical media within a certain viscosity range, especially for high-precision measurement and custody transfer applications.

Advantages:

High accuracy, wide turndown ratio, simple maintenance, and low requirements for fluid cleanliness.

III. Comparison Table of Key Flowmeter Parameters

| Flowmeter Type | Key Advantages | Suitable Media |

| Scraper Flowmeter | Resistant to solid particles, extremely high accuracy, ideal for crude oil custody transfer | Crude oil, heavy oil, refined oil |

| Dual-Rotor Flowmeter | High accuracy, low noise, no pulsation, long service life, excellent operational stability | Crude oil, refined oil, high-temperature & high-viscosity media, corrosive media |

| Roots Flowmeter (Lobe Flowmeter) | Fast response, strong stability | Diesel |

| Oval Gear Flowmeter | Strong adaptability to viscosity; higher viscosity results in higher measurement accuracy | Crude oil, refined oil, high-temperature & high-viscosity media, chemical fluids |

| Mass Flowmeter (Coriolis Flowmeter) | Direct mass measurement, multi-parameter output, high accuracy | Oil products and chemical media within a certain viscosity range |

IV. Development Trends in Flowmeter Technology

Traditional flowmeters mainly rely on 4–20 mA analog signals and RS-485/Modbus digital communication for remote data transmission and require manual inspection and calibration. With technological advancements, flowmeters are evolving toward intelligent, localized, and networked solutions.

In terms of intelligence, next-generation flowmeters integrate high-performance microprocessors with edge computing capabilities, enabling on-device data filtering, temperature and pressure compensation, self-diagnostics, fault alarms, wireless transmission, and multi-parameter fusion. These features significantly reduce manual maintenance costs.

Regarding localization, key devices such as Coriolis mass flowmeters and large-diameter scraper flowmeters have achieved major technological breakthroughs. Their accuracy and stability now reach international advanced levels while offering advantages in cost and after-sales response compared to imported equipment.

Looking ahead, with the integration of AI, 5G, and digital twin technologies, flowmeters will no longer function as standalone instruments. Instead, they will be deeply embedded into smart pipeline systems, providing real-time data interaction to support intelligent dispatching, leak detection, and energy optimization—driving the digital transformation of the oil storage and transportation industry.

Address: No.75, Science Avenue, Hi-Tech Zone, Hefei City,China

Tel: +8618956032415

E-mail: jingda1958@gmail.com

WhatsApp: +8618956032415