Common Faults and Troubleshooting for Oval Gear Flow Meters

Release time: 2025-06-26

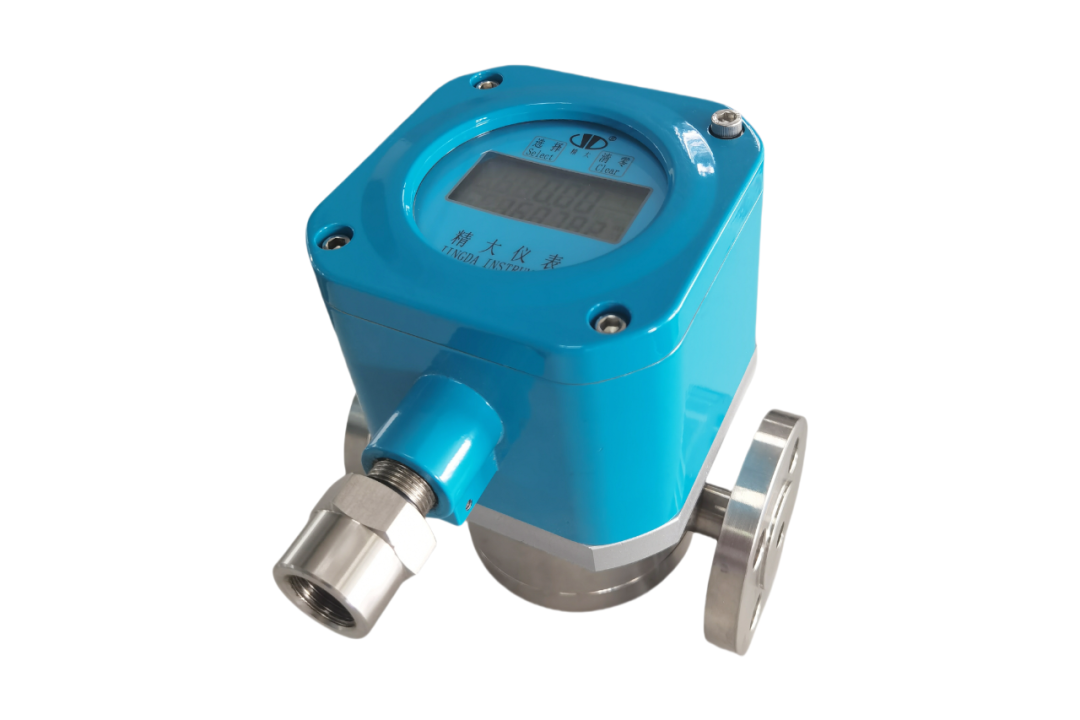

The oval gear flowmeter is an instrument commonly used to accurately measure fluid flow and is widely used in the petroleum, chemical, pharmaceutical and other industries. It measures the flow of fluid by meshing between gears, using oval gear elements to continuously divide the fluid into single known volume parts, and measures the total volume of flow according to the number of times the metering chamber is filled and discharged repeatedly.

However, after long-term use, some common faults may be encountered. The following are common troubleshooting methods and maintenance tips for oval gear flowmeters:

Common faults and troubleshooting methods

1. Inaccurate flowmeter readings

Reason:

Changes in fluid properties (such as viscosity and density changes).

Wear and damage of gears caused by external forces and damage.

Troubleshooting methods:

Check whether the physical properties of the fluid have changed, and recalibrate the flowmeter if necessary.

Check whether the oval gear is worn or damaged, and replace it if damaged.

Clean up bubbles or solid impurities in the flowmeter and pipeline to ensure smooth flow of fluid.

2. Flow Meter Shows High or Low Values

Causes:

Fault in the flow meter’s sensor.

Fluid flow rate is too high or too low.

The system’s pressure is too low or too high.

Troubleshooting:

Inspect the sensor to ensure it’s functioning properly. Replace the sensor if needed.

Adjust the fluid flow rate to fall within the specified range.

Check and adjust the system’s pressure to ensure it is within the recommended operating range.

3. No Data Display on Flow Meter

Causes:

Electrical connection failure or signal transmission interruption.

Low battery (if battery-powered).

Troubleshooting:

Inspect the electrical connections to ensure they are secure and the signal is being transmitted properly.

Check the battery level and replace the battery if it’s low.

4. Flow Meter Vibrating or Making Noise

Causes:

Gear wear or imbalance.

Excessive air bubbles or solid particles in the fluid.

Troubleshooting:

Inspect the oval gears for wear or damage, and replace them if necessary.

Remove air bubbles or solid particles from the fluid to ensure smooth flow.

5. Flow Meter Leaking

Causes:

Worn or damaged seals.

Improper installation.

Troubleshooting:

Check the seals for damage and replace them if necessary.

Inspect the installation to ensure it complies with the standards, and verify there are no leaks at the connections.

Common Maintenance Tips

1. Regular Calibration

Perform regular calibration of the liquid flow meter, especially after prolonged use, to ensure accurate measurements. Use a standard flow source for calibration and verify the meter’s accuracy.

Inspect Gear Wear

Regularly check the oval gears for signs of wear. Gear wear can lead to inaccurate measurements, so it’s essential to replace gears that are heavily worn.

2. Clean Fluid Impurities

During operation, impurities like solid particles or air bubbles in the fluid can affect the flow meter’s performance. Regularly clean the meter and pipeline to ensure unobstructed fluid flow.

Inspect and Replace Seals

Periodically check the flow meter’s seals to prevent leaks caused by aging or damage. Replace the seals as needed.

3. Check Electrical Connections Regularly

For the electrical components, periodically inspect terminals, sensors, and other parts to ensure no loosening, corrosion, or damage. Maintain good electrical contact to prevent signal loss.

4. Avoid Overloading

Ensure that the flow meter does not exceed its maximum rated flow. Overloading can cause gear damage, seal leakage, and other issues.

5. Control Temperature and Pressure Properly

Ensure the flow meter operates within its specified temperature and pressure range to avoid malfunctions due to extreme conditions. Use temperature and pressure sensors for monitoring.

6. Regularly Inspect External Equipment

Ensure that the connected equipment, such as pipes, pumps, and valves, is working properly to prevent faults in these external devices from affecting the flow meter’s accuracy.

By performing regular maintenance and troubleshooting faults promptly, precision oval gear flow meters can operate reliably and provide accurate flow measurements over a long period.